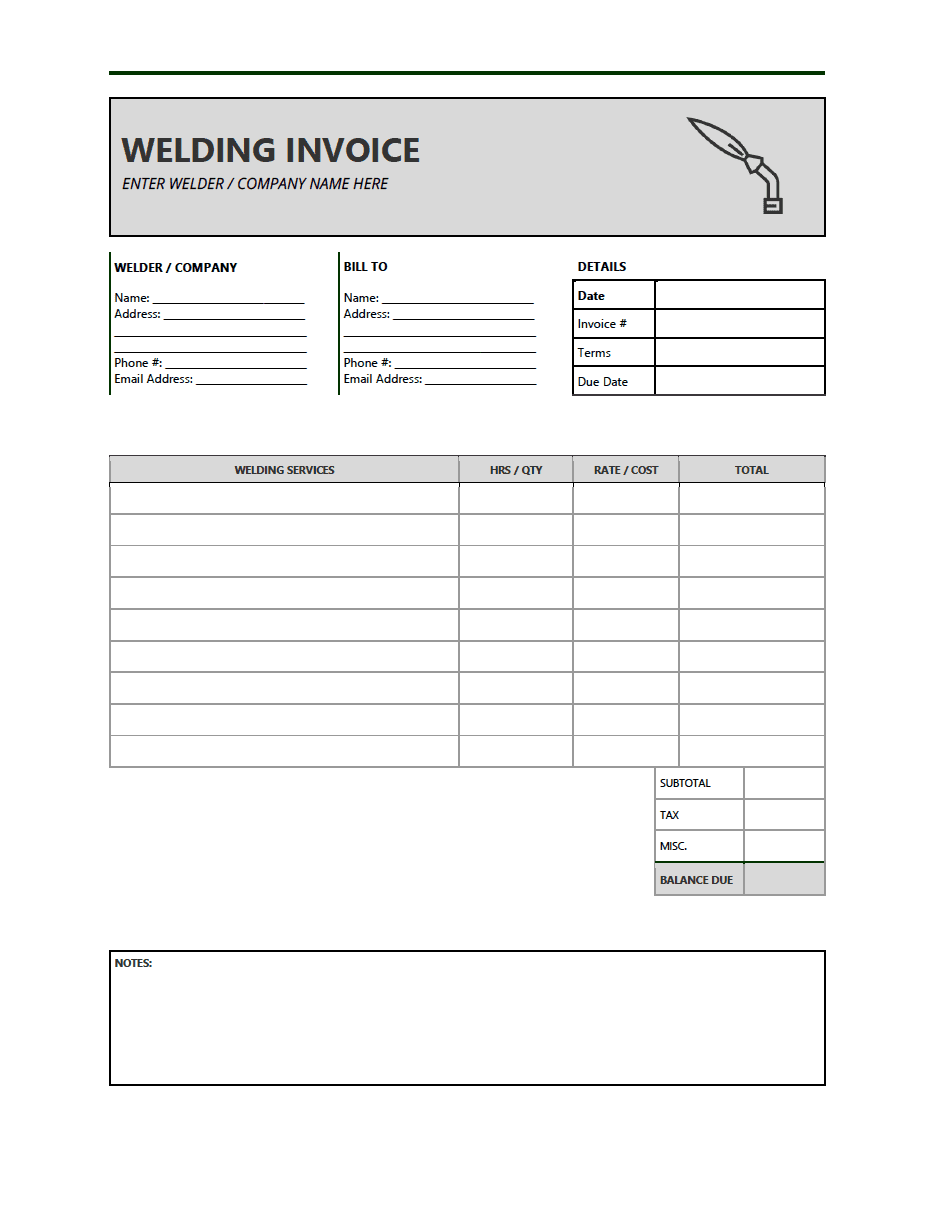

Welding Invoice Template

A welding invoice is a printed bill that cleanly outlines the money owed for one (1) or more services provided by a contracted welder, self-employed professional, or larger-scale fabrication companies. The invoice incorporates the price per hour ($/hr) in addition to any material fees. Depending on the project, the welder may offer standard prices for commonly provided tasks instead of charging by the hour. Additionally, the welder’s invoice covers when payment is due, includes any special notes for the service(s), and contains a place to include an invoice number (#) for accounting purposes.

Download: Adobe PDF, MS Word (.docx), MS Excel (.xlsx)

What does a Welder do?

A welder uses tools that create intense heat to splice together pieces of metal or to smooth and polish existing surfaces made from metal, as well as patch up holes. The job is formidable, and welders work on the infrastructure of our country, including bridges, pipelines, power plants, and buildings. Beyond the physical requirements of the job, a welder needs to be able to read blueprints and understand measurements and dimensions. Before they work on soldering metal together, a welder needs to inspect the materials and framework.

The job of a welder is not for the faint of heart. They usually must work outside, in all sorts of weather, and sometimes are exposed to hazardous working conditions. From working inside pipes, to going underground, to scaling the tops of bridges and buildings, welders are faced with a unique set of challenges each day. They also typically work overtime often, as you cannot really leave a job half-finished in this line of work.

Types of Welding

MIG welding uses a gas metal arc to fuse steel or aluminum and is the most common type of welding. TIG uses tungsten inert gas for its fusion and is used when a high-quality weld is required. Arc welding is often used in private homes and offers a basic fusion. It is also known as stick welding. Understanding these differences in welding techniques is all part of the job.

How to Become a Welder

As long as you have the interest and the tough-mindedness, becoming a welder is not very difficult. You need to have a high school diploma or GED to start and can get a welder’s certificate at a local community college or vocational school later on. These certifications will teach you the basic requirements of welding, get you familiar with the types of welding you will be required to perform, and generally teach you the vocabulary, terminology, and techniques you need to know.

After receiving your certificate, you will typically have a three-year apprenticeship where you will work with a master welder and learn the technicalities of the job via this on the job training. Working with a seasoned professional will help you to learn how to troubleshoot in a variety of situations, and give you priceless on-the-job training and experience.

The next step is to get certified with the American Welders Society. This will make you much more marketable as a welding professional and usually leads to higher salaries, more leadership positions, and better jobs in the future. Often welders will join the local Ironworkers Union to gain the support of like-minded professionals.

How to Charge for Welding

There are two elements you need to consider when pricing welding jobs. First, you need to make sure the fee will cover your overhead, fuel costs, materials, and wear and tear on your vehicles and tools. Overhead also factors in the cost of your insurance, your license, and any miscellaneous costs. After determining the typical cost of your overhead, you will then add to that your hourly fee. Welders who are just starting out typically make $15-20 dollars an hour. After a few years on the job, your hourly rate will jump to $20-30 dollars an hour. Once you add the hourly wage to the overhead cost, you are ready to write your invoice.

Because the scope of welding jobs runs the gamut from a one day job at a residential home, to jobs that last weeks and even months at various large companies, each invoice will be different. If the job is large in scope, you may need to price it out for a number of days rather than a number of hours. When billing customers, mailing the bill and allowing them to mail it back or use a credit card over the phone is a great way to do business.

Finally, when dealing with the materials for specific welding jobs, welders often have the customer pay for the materials directly so the welder himself does not have to put any money upfront. This allows the welder to have the materials on hand when needed, without breaking his own bank in the process.